With multiple injection molding and encapsulating process and materials of different hardness chosen for different parts, CG-001 grips can achieve the best use effect and satisfy various needs. The copolymerized PP molding used for the grip framework not only satisfies its supporting need, but ensures its good effect of shock absorption. It’s well-known that the palms would be numb for the compression on the blood vessels and nerves caused by the long-term riding. Therefore, the softness and proper texture design of the surface material as well as the reasonable hardness of the middle material will definitely play a significant role in avoiding the compression and providing sufficient support. It’s believed that, with different materials chosen for the surface, middle and supporting parts of CG-001 which are integrated by the multiple injection molding and encapsulating process, both good support and comfort can be guaranteed.

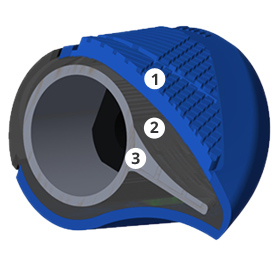

The sleeves are made of different materials by using the most complicated multiple encapsulation process to manufacture the skeleton buffer layer and the surface layer.

- 1

The surface layer is made of 35 degree high-quality medical rubber with abrasion resistance and adhesion, softness, elasticity and anti-aging performance.

- 2

The buffer layer is made of 55 degree high-quality medical rubber with a good elasticity and shock absorption.

- 3

Frame of frame, made of PP. Has good support and toughness.

The diameter of the plug is the same as the diameter of the aluminum ring, which can prevent the handle from being damaged when removing the plug.

- 1

Concealed design conceals screws inside the sleeve

COSY GRIPS By combining various latest technologies, CG-001 grips have achieved great improvement in its comprehensive performance and comfort, and carefully adjusted its hardness of materials, mechanical properties as well as handfeel. In addition, to meet its design requirements, the latest multiple injection molding and encapsulating process has been used to make CG-001 more beautiful and convenient from appearance to installation with proper structure design. Let’s experience the surprise of COSY GRIPS together.

COSY GRIPS Optimization has been made for the anti-skid design of CG-001, which serves as the important role, especially in mountain biking as well as athletics. After many optimization experiments, the good anti-skid effect and superior handfeel as well as comfort of the scale and diamond patterns of CG-001 have been verified. On the top, the key part of the grip, the shape of the scale patterns can change with the fingers to ensure better comfort and grip; While the design of the diamond patterns on the link between the fingers and the palm can better fit our finger joints to the surface to easily grip. In addition, the rough grooves can effectively drain away water and sweat to ensure your riding dry and cool.

- 1

The diamond pattern and grooves on the front reduce the contact surface and make it comfortable to use. At the same time, it can keep the surface as dry as possible when it is wet.

- 2

Fish scale pattern has good comfort and non-slip

Separate the sleeves on the support palms for independent partitioning. The large grooves around and in the middle are used to drain water to prevent the surface area of the sleeves from raining. The main function of the chute and diamond pattern in the area is anti-skid and decompression. Avoid numb palms caused by prolonged cycling.

- 1

Non-slip area, diagonal stripes

- 2

Decompression area, diamond pattern

COSY GRIPS The 35℃ thermoplastic rubber of Jilishi was used to fill in the core decompression area of CG-001; While the 55℃ thermoplastic rubber of Jilishi was used in the middle layer. Such design can effectively soften this surface and ensure appropriate support to avoid the compression at its maximum. The design of strip and diamond patterns on the surface as well as the partition process is also for decompression and skid resistance for the combination of flexible glue and patterns can avoid compression at its maximum. Meanwhile, the strip grooves can effectively drain away water and sweat to ensure the support area dry and comfortable. Without compression, the numbness of palms can be avoided effectively and riding will be much healthier.

COSY GRIPS The hidden locking ring structure used by CG-001 can effectively avoid the problems of inconvenient disassembly as well as insecurity of no-locking ring structure, and high cost of the external aluminum ring and surface corrosion after a long-term use. In addition, the design of a stainless steel gasket between the locking ring and the grip pipe in the built-in aluminum ring structure can avoid the damages of the locking ring to the handle bar

The built-in structure of the locking ring makes the product more beautiful, while making the user safer and more comfortable. Product replacement is also easier.

- 1

Lock screw

- 2

Locking aluminum ring

- 3

Stainless steel gasket

Product parameters

- Brand :

- Cosy saddle

- Weight :

- 265g

- Size:

- 275*145mm

- Type :

- Customization type

- Color:

- Black

- Padding :

- High elastic PU foam

- Shell material :

- Nylon glass fiber reinforced

- Rail:

- CR-MO

- Thickness:

- 1.4mm

- Leather:

- High strength PU leather with superior anti-aging and scratch resistance, thickness 1mm.

- Features:

- Support customization,Bigger hollow with “zero” oppression,Non-toxic ,healthy

Passed the restriction testing of 243 items hazardous substances

- PAHS:

- 18 items

- DMFa :

- 18 items

- SVHC :

- 201 items

- ROSH :

- 8 items

- SCCP :

- Short Chain Chlorinated Paraffins

- Phthalates PAEs ::

- 14 items